Minimum Continuous Flow

There are three factors which must be looked at with respect to minimum flow. These are:

- Mechanical ability - this is the ability of the pump to withstand all of the forces (side thrust, axial thrust, vibration, etc. ) associated with operating the pump at low flows.

- Hydraulic stability - this is the stability of the pump to operate at flow rates other than the Best Efficiency Point (or nearby), particularly low flow rates as a percentage of the BEP, without detrimental internal recirculation, hydraulic instabilities, etc. that can cause pump damage.

- Thermal stability - has to with the properties of the particular liquid being pumped and the effects of heat (temperature) rise to liquid. See HEAT INPUT above for a discussion of temperature rise. A commonly accepted conservative temperature rise through a pump is 15 deg. F. For a 15 deg. F rise, the minimum flow can be calculated as follows:

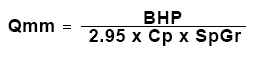

|

||||

| Where Qmm | = | minimum flow rate for 15 deg. F temp rise. (GPM) | ||

| BHP | = | the power input at the minimum flow. (BHP) | ||

| 2.95 | = | constant, for 15 deg. F rise (HP-Lb-Min-deg. F/BTU-Gal.) | ||

| Note: for 20 deg. F rise use 3.93 instead of 2.95. | ||||

| Note: for 10 deg. F rise use 1.96 instead of 2.95. | ||||

| Note: for 5 deg. F rise use 1.00 instead of 2.95. | ||||

| Cp | = | specific heat, (BTU/lb-deg. F). | ||

| SpGr | = | Specific Gravity of the pumped fluid. |

It is important to understand that a catastrophic failure of any pump can occur if the liquid within the pump casing is allowed to vaporize. To prevent flashing, a flow must be maintained through the pump which will keep the liquid below its saturation temperature.