NPSH and Cavitation

The Hydraulic Institute defines NPSH as the total suction head in feet absolute, determined at the suction nozzle and corrected to datum, less the vapor pressure of the liquid in feet absolute. Simply stated, it is an analysis of energy conditions on the suction side of a pump to determine if the liquid will vaporize at the lowest pressure point in the pump.

The pressure which a liquid exerts on its surroundings is dependent upon its temperature. This pressure, called vapor pressure, is a unique characteristic of every fluid and increases with increasing temperature. When the vapor pressure within the fluid reaches the pressure of the surrounding medium, the fluid begins to vaporize or boil. The temperature at which this vaporization occurs will decrease as the pressure of the surrounding medium decreases.

A liquid increases greatly in volume when it vaporizes. One cubic foot of water at room temperature becomes 1700 cu. ft. of vapor at the same temperature.

It is obvious from the above that if we are to pump a fluid effectively, we must keep it in liquid form. NPSH is simply a measure of the amount of suction head present to prevent this vapor fluxion at the lowest pressure point in the pump.

NPSH required is a function of the pump design. As the liquid passes from the pump suction to the eye of the impeller, the velocity increases and the pressure decreases. There are also pressure losses due to shock and turbulence as the liquid strikes the impeller. The centrifugal force of the impeller vanes increases the velocity and decreases the pressure of the liquid The NPSH Required is the positive head in feet absolute require at the pump suction to overcome these pressure drops in the pump and maintain the liquid above its vapor pressure. The NPSH required varies with speed and capacity within any particular pump. Pump manufacturer's curves normally provide this information.

NPSH available is a function of the system in which the pump operates. It is the excess pressure of the liquid in feet absolute over its vapor pressure as it arrives at the pump suction.

PB = Barometric pressure, in feet absolute.

p = Pressure on surface of liquid in closed suction tank, in feet absolute.

LH = Maximum static suction head in feet.

VP = Vapor pressure of the liquid at maximum pumping temperature, in feet absolute.

Ls = Maximum static suction lift in feet.

hf = Friction loss in feet in suction pipe at required capacity.

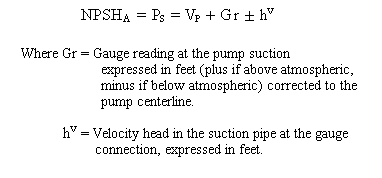

In an existing system, the NPSH Available can be determined by a gauge on the pump suction. The following formula applies:

Cavitation is a term used to describe the phenomenon which occurs in a pump when there is insufficient NPSH Available. The pressure of the liquid is reduced to a value equal to or below its vapor pressure and small vapor bubbles or pockets begin to form. As these vapor bubbles move along the impeller vanes to a higher pressure area, they rapidly collapse.

The collapse, or "implosion" is so rapid that it may be heard as a rumbling noise, as if you were pumping gravel. The forces during the collapse are generally high enough to cause minute pockets of fatigue failure on the impeller vane surfaces. This action may be progressive, and under severe conditions can cause serious pitting damage to the impeller.

The accompanying noise is the easiest way to recognize cavitation. Besides impeller damage, cavitation normally results in reduced capacity due to the vapor present in the pump. Also, the head may be reduced and unstable and the power consumption may be erratic. Vibration and mechanical damage such as bearing failure can also occur as a result of operating in cavitation.

The only way to prevent the undesirable effects of cavitation is to insure that the NPSH Available in the system is greater than the NPSH Required by the pump.